Do Oklahoma’s outdated rules open the door for Federal intervention?

Executive Summary

Problem: Oklahoma’s outdated drilling waste management rules and practices related to land application of solid waste.

Threat: EPA intervention, continuing improper use of land, loss of landowner support.

Consequences: EPA shifts the rules, and Oklahoma is forced to change to their guidelines leading to drastic market changes, increasing costs, and expanded liabilities. This has the potential to dissuade operators from investing in the state, which would have repercussions for all constituents and stakeholders. The harm done to downstream businesses and individuals dependent on them could further reverse the growth we’ve seen over the past two decades.

Solution: Oklahomans modify regulations for Oklahoma, inviting new investment, modernization, and environmental responsibility related drilling waste management practices on Oklahoma’s terms, not Washington’s.

Introduction

Every Oklahoman knows the words to our state song, “we know we belong to the land and the land we belong to is grand,” but when it comes to oil and gas solid waste practices, are we really “doing fine”? And are we headed toward a job-killing run in with the EPA?

Given the importance of Oklahoma’s oil and gas production in powering the nation’s economy and the industry’s role in providing jobs in the state, concerns exist about the impacts our outdated waste regulations could have on the future of drilling. Oklahoma’s reliance on land application as its primary and nearly sole method of solid drilling waste disposal has been characterized by professionals in the waste management space as a looming environmental liability. A “job-killer” waiting to happen could invite intervention from an increasingly activist EPA if not remedied. Federal intervention on oil and gas waste is becoming increasingly likely. If enacted, it would impose excessive costs in Oklahoma, which would lead operators to head for greener pastures such as Texas, New Mexico, Wyoming, North Dakota, and Louisiana, taking jobs and investment with them.

It’s time we update our solid waste rules, safeguard our land, secure our resources, and shield ourselves from an ever-changing Washington DC. Not only will it protect the industry jobs we have today, but it will also lead to new investments tomorrow.

Outside threats to Oklahoma’s oil and gas industry:

For examples of the threat to the Oklahoma oil and gas industry, look no further than recent stories from Bloomberg Law and other outlets pointing to oil and gas waste as the next target of the ESG movement. According to the July 2021 article, Bloomberg states, “federal and state regulators have known about the health risks of radiation from oil and gas production, but gaps and carve-outs in federal environmental laws and weak or non-existent state regulations have left workers, the public, and clean water at risk.” The report goes on to point to drilling waste as the primary concern. In October of 2021, E&E News published a memo from EPA administrator Michael Regan stating, “The Biden EPA’s strategic plan, covering fiscal 2022 through fiscal 2026, has seven goals and four cross-agency strategies. Those four strategies focus on scientific integrity, children’s health; workforce equity; and engagement with state, local and tribal governments. Along with climate change and environmental justice, the plan’s goals are enforcing environmental laws, clean air, clean water, waste and environmental emergencies, as well as chemical safety. Or this from an open letter published in IOP Science “The RCRA exemption as a hidden subsidy to the industry.” A “Transfer of financial liability to the government/state/taxpayer leading to underpriced risk accounting in many states.” How do we know Oklahoma is specifically at risk? How can its waste regulations impact the industry and its countless associated jobs? A review of the coal industry and the federal rules regarding coal waste will provide a roadmap. The following analysis of the regulatory history of drilling waste in Oklahoma and comparison to other states should clarify the need to change current waste processes and modernize how we do business.

What is drilling waste? Drilling waste covers the spectrum of fluids and solids that are a byproduct of drilling or drilling-related activities. The mud used to lubricate the drill bit and ground up rock is commonly called “cuttings and muds,” The water is called “fluids or produced water.” This waste may contain harmful constituents such as salts, heavy metals, and waste oil.

Pre RCRA and the early days of land spreading waste

As a requirement of creating the Federal Resource Conservation and Recovery Act (RCRA) in the late 70’s the EPA was tasked with reviewing historic oil and gas waste management practices within the different states and reporting their findings back to congress. Their initial report to Congress found the widely adopted use of reserve pits as the primary disposal method and land application as a secondary disposal method. Before we go further, let’s take a step back and review the different disposal methods for oil and gas waste.

Before RCRA, operators managed their waste however they wanted to a large extent, leading to scenes like the one in the postcard above (Blue arrows are pointing to waste pits and open flowing waste)

From its earliest days, the industry settled on two leading disposal practices. Pits (a hole in the ground or an artificial pond with compacted dirt) and, to a lesser extent, land spreading, also known as land farming, soil farming, or land application (spreading raw waste on the ground). In drier climates, the operator would let the water in the pit evaporate, then mix the solid waste cuttings and muds with soil and bury it. In wetter climates, operators would often spray or spread the liquid waste on the land adjacent to the wellsite, leaving the solids in the pit, which they would then trench and bury.

Soon after the creation of RCRA, Oklahoma actually prohibited land spreading of oilfield waste, citing the contaminant constituents found by both the API and the EPA during their broad-based nationwide testing of oilfield waste. The contaminates the EPA found most prevalently were the “heavy 8 metals” now known as the RCRA 8; this includes arsenic, barium, cadmium, chromium, lead, mercury, selenium, and silver. The other significant pollutants they pointed to were salts and crude oil. Based on these findings, Oklahoma regulatory framework around oil and gas waste focused on the “pit – dry – bury” method. Since the vast majority of wells drilled during that time were in the Anadarko basin of western Oklahoma, this method fit what the industry needed.

Initial Rules

Fast forward to the Penn Square collapse; the rigs were gone from the landscape, and so were the jobs. As will become a consistent theme throughout the next few decades of booms and busts, on the way down, both operators and service companies feel the squeeze, fewer jobs for lots of service companies lead to cost-cutting measures. One such cost cutting measure was that oil and gas waste pits could be made smaller and closed faster if the fluid on top of the mud was sprayed or spread out of the pit and onto the adjacent farmland. Service companies and operators alike pressured the Corporation Commission to relax its rules related to land spreading, an effort that was finally successful in 1986, the depth of the bust. On October 17th, the business section of the Daily Oklahoman read as follows “the state's first comprehensive set of rules allowing and governing non-commercial "soil farming" of water-based muds and cuttings from oil and gas drilling or production. Soil farming is defined by the rules as "application of oil-field drilling or produced wastes to the soil for the purpose of disposing of the waste without being a detriment to water or land. “non-commercial soil farming means one-time application of these materials to a property. The rules forbid commercial soil farming and soil farming of oil-based muds. The rules require anyone wanting to soil farm oil-field materials to get a Corporation Commission permit. The only ones who may apply for such permits are operators of "reserve pits," generally the pits dug next to a well site to contain fluids used in drilling or operating the well.” It went on to describe in more detail what the Commission outlined for guidance on land spreading “Oil-field drilling muds can contain a variety of heavy metals and other substances. The rules limit concentrations of many such materials that may be applied during soil farming. For instance, the rules cap the "loading rate" per acre for arsenic at 80 pounds, for chromium at 40 pounds, for cadmium at 5 pounds and for the total weight of applied materials at 400,000 pounds. The rules require that any attempt to re-establish vegetative cover be made within 120 days of Soil completion of soil farming.”

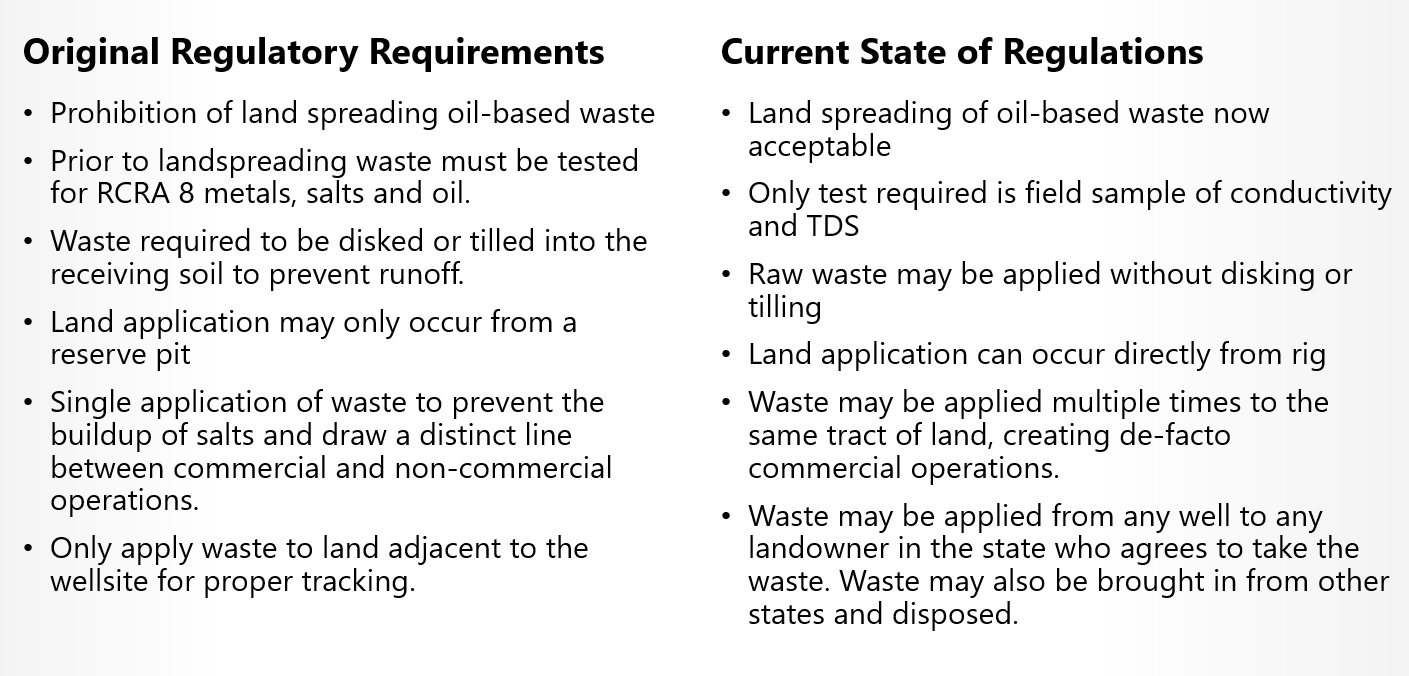

It should be noted that Oklahoma’s original rules were built on the following criteria and core principles:

- Waste to be applied to the land was contemplated to be only water-based fluids (not solids)

- Test both the waste and soil on which it will be spread for the RCRA 8 metals, salts, and oil.

- Only apply waste to land adjacent to the wellsite for proper tracking.

- Only apply waste to the land once to prevent the buildup of salts and metals.

- Land application may only occur from a reserve pit.

- Waste would be disked into the receiving soil after spreading to prevent runoff into surface water.

Land spreading of oil-based fluids and solids were prohibited

These core regulatory principles associated with land spreading were contemporaneously adopted in other states such as Louisiana, Texas, and Wyoming. The primary differentiation was that Texas and Wyoming capped the salt limit of waste at 3,000 ppm. These similar “core principles” shared with other states would change drastically in the coming decades.

When an oil bust, farm bust, and drilling waste meet

As the energy industry in Oklahoma continued to languish in the poor prices of the 1990s, the farm bust of the prior decade could still be felt in the equipment auctions that were frequently held in western Oklahoma. Changes were also happening in the drilling industry; stricter environmental regulations around reserve pits were being passed in multiple states, causing the industry to modernize how waste was managed during the drilling process. One of the most significant technological advances of this time was the rise of “closed-loop drilling,” which is an alternative to reserve pits where the flow path of waste is not open to the atmosphere. In a closed-loop system, a series of tanks are used together with specialized equipment (e.g., screen shakers, hydrocyclones, centrifuges) to separate drilling fluid from drill cuttings and other solids (known as solids control equipment). This process minimizes the amount of fluid retained on the waste solids and maximizes the amount of fluid recycled back into the drilling process. Minimizing the volume of waste solids through fluid removal results in less waste ultimately disposed of. This new pit-less drilling was combined with an experimental method of applying waste to the land via agricultural spreaders. This process would allow operators to forgo digging an expensive pit and, if taken directly from the rig and spread on the ground, would also remove the cost of the more expensive pieces of solids control equipment. However, the procedure conflicted with established rules regarding soil farming. Land spreading service companies made new requests for rule changes. At this point, Oklahoma diverged from every other state in how it regulated drilling waste management, a legacy that still reverberates today.

Land spreading service companies initially favored the use of ag spreaders due to their ability to travel over plowed ground as the original rules required viscous mud and cuttings to be disked or tilled into the receiving soil. Even ranchland was required to be disked to prevent waste from running off into nearby waterways. As “pitless” drilling increased and the amount of solids needing to be landfarmed increased, the state shifted away from the disking/tilling requirements.

Compromises in testing and application methods

The first significant compromises came when service companies argued that the surface water, groundwater, and soil could be protected with less waste testing prior to land spreading. In reality, the only test that would fit this new system of taking waste directly from the rig and spreading it onto the field would be tests that could be performed real-time in the field. And that is precisely what happened; the testing requirements shrunk from the 8 metals, salts (tested via conductivity and TDS), and oil and grease to only Conductivity and TDS. The justification was that metals could not build up because this was a one-time application, and there was no need to test for oil because land application was only being performed with water-based fluids. From a regulatory standpoint, Oklahoma became and remains the only state to grant a waste management permit to land spread waste before that waste is tested for potentially harmful constituents.

Rise of horizontal drilling and further compromises on rules

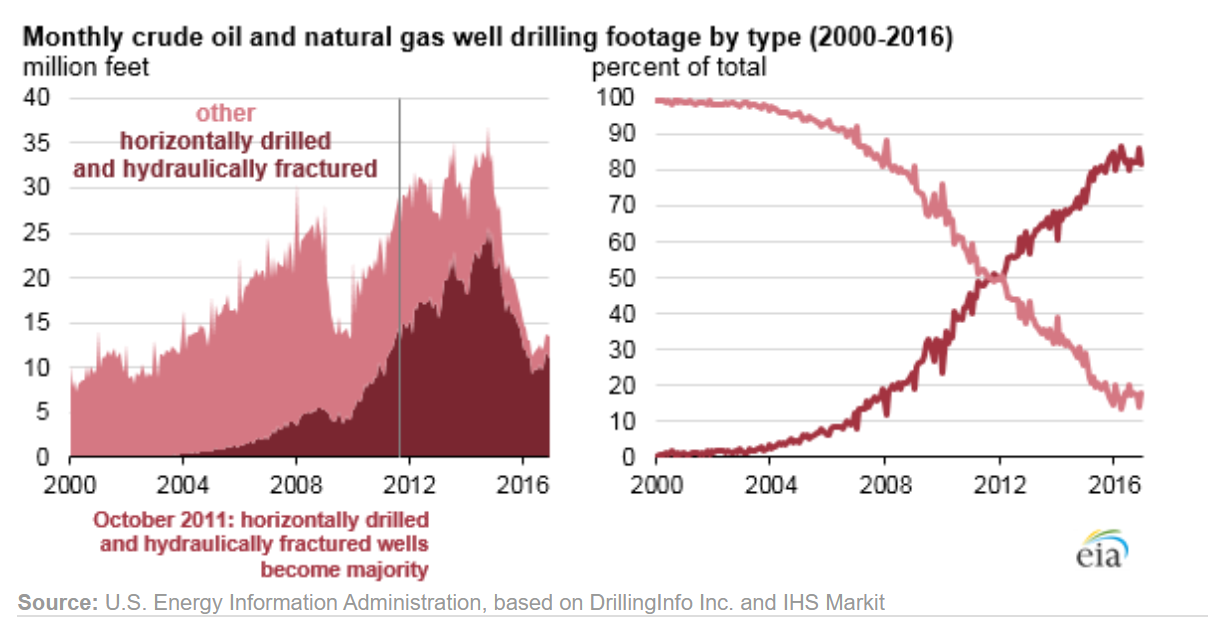

Perhaps one of the greatest innovations in the extractive energy space has been horizontal drilling; this drilling method which became widespread in the early 2000s, has unlocked previously uneconomical fields and led to a resurgence of the US onshore drilling market.

One of the discoveries that operators made was that it was nearly impossible to keep the wellbore stable when drilling horizontally, so to “keep the string straight,” companies changed what they used to lubricate the drillbit from water-based mud to oil-based mud (mud that is saturated by infusion with diesel). Another compromise was made, and land spreading of oil-based fluids and solids, a practiced banned since 1986, was now allowed to be spread on the ground. Oklahoma again became the only state in the United States to allow the practice in its current form.

The big shift: States experiencing a resurgence of drilling modernize their waste rules while Oklahoma regresses

Not only did drilling activity increase rapidly between 2004-2014, but so did the amount of waste generated from each well. The equation is simple the further you drill, the more waste you create; wells drilled before 2004 averaged around 3,000 – 5,000 feet in total depth; today, the average depth has nearly tripled. To keep up with these rapid changes, a flood of new rules was adopted by states around the country. These new rules aimed to protect the environment and adapt to the changing landscape of modern oil and gas exploration. A modernized regulatory framework was taking shape around the country, and states began moving away from outdated disposal methods towards practices like large scale commercial monofills and advanced recycling. In Oklahoma, the rule changes went the opposite direction and were implemented to make land spreading acceptable. Oklahoma’s approach to rulemaking led to an increasingly lengthy and confusing set of rules. Unlike other states that reduced or banned some outdated disposal practices and replaced them with new streamlined frameworks, Oklahoma just added a new rule for each innovation related to drilling. This approach has led to a patchwork of environmental regulations that have become some of the longest and most antiquated in the nation. By the end of the 2000s, original tenets of ecological protection were gone, and Oklahoma found itself alone in how it managed drilling waste.

The following table reflects Oklahoma's current state of regulatory oversight and how far we’ve gone to protect an outdated waste management system.

Change to allow multiple applications to the land and Temporary pits

Two of the worst environmental changes involved repealing the requirement of “one time” land spreading and the allowance of temporary pits. These changes lead to what could now be described as a series of de-facto commercial operations since every landowner in the state can now theoretically take waste from multiple operators and apply it multiple times to their property. The other environmentally risky decision was the allowance of temporary pits. This was driven by the fact that land spreading is proven to lead to waste discharge into nearby surface water if performed during a precipitation event. So, to stockpile waste during rain events, the Commission allowed what are known as “temporary pits” these pits are hastily created and come with none of the construction requirements that the old reserve pits had—leading to images like the ones below taking place in pastures and farmland throughout the state.

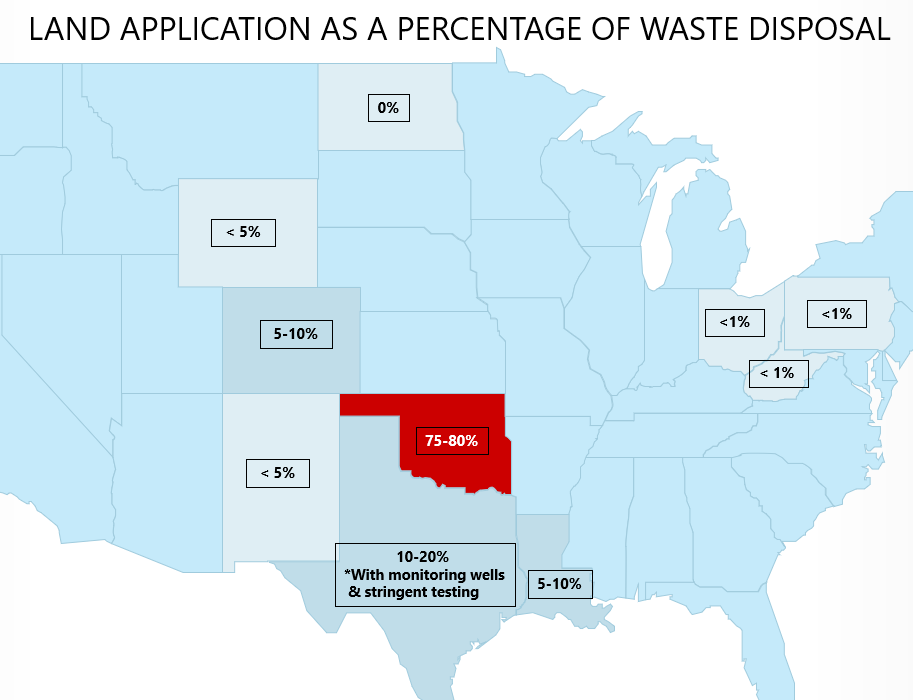

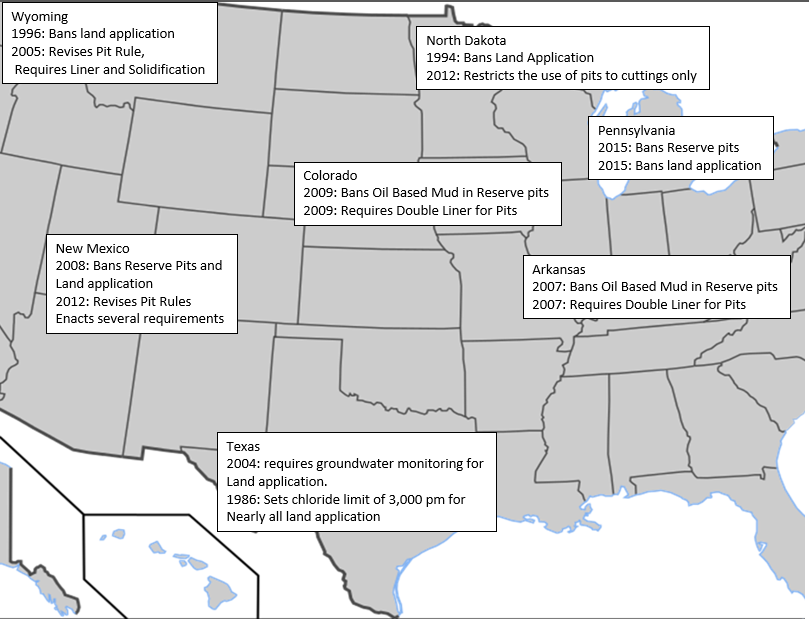

State by State comparisons on regulations, testing, and infrastructure

What was happening in other states during this time? Nearly every state where oil and gas exploration increased due to the shale revolution revised their waste management regulations, and almost all went the opposite way of Oklahoma. Instead of loosening their environmental protections, they modernized, banning older waste practices like unlined pits and land spreading and creating a framework that encouraged recycling and monofil style commercial facilities. These regulatory changes resulted in an influx of new money being poured in from publicly traded service companies. Millions of dollars per state were invested in upgrading and creating new waste management infrastructures. The following map details major regulatory revisions in the top oil and gas producing states.

Nearly all active oil & gas states have modernized their waste policy in response to industry changes

Obama – Trump administration EPA and environmental sue and settle lawsuits

Following the success, the technique coined “sue and settle” had on reforming the coal industry environmental groups focused on oil and gas and specifically how states managed waste regulations. In May of 2016, a coalition of community and environmental organizations filed a federal lawsuit against the U.S. Environmental Protection Agency today, calling for regulations to stop oil and gas companies from disposing and handling drilling and fracking wastes in ways they claimed threaten public health and the environment. The lawsuit, if settled upon, would have called for the elimination of all land application throughout the US. However, the case would take a different direction as six months later, Donald Trump was elected to office, and Scott Pruitt of Oklahoma was tapped to lead the EPA. This turn of events led to the EPA simply conceding that the EPA should review its waste policies, a task they undertook in 2019 with the conclusion that no new regulations needed to be enacted. In conceding the need to review and, if needed, revise regulatory policy regarding drilling waste, the EPA reaffirmed the original congressional mandate that drilling waste management be reviewed by the EPA no less than every three years. That clock started in March 2019, and a new review will be called for no later than April 2022, squarely in the middle of the Biden administration’s first term. As seen in the previous quote from the EPA administrator, oil and gas waste is and will be in the crosshairs of that federal agency.

Recent studies on surface water impacts from waste

In August of 2021, a paper was published in the Journal Science titled Large-sample evidence on the impact of unconventional oil and gas development on surface waters. The conclusion of the research was as follows: “Overall, our evidence complements prior studies on the impacts of unconventional O&G development on water quality and extends studies using a similar large-scale approach for the Marcellus Shale. Our statistical approach does not reveal the exact mechanism for the association between new HF wells and concentration increases. There are three potential channels that are particularly relevant in our context: (i) on-site accidents; leaks and spills of HF fluids, flowback, and produced water, including those related to pits (overflow, unlined pits, tears in liners); brine trucking; and long-term leaching of soils after spills; (ii) direct disposal of untreated wastewater from HF operations (unauthorized or permitted); and (iii) inadequate treatment of wastewater at disposal sites. We do not distinguish between these specific channels. However, the consistent increases in ion concentrations shortly after well completion, for wells with large amounts of produced water and wells located in areas with high salinity deep formations point to the handling of flowback and produced waters, including leaks and spills, being part of the mechanism for the well–ion association we documented. We explored other explanations and found that our results for HF wells do not reflect the presence of facilities accepting HF wastewater in a watershed, are not observed for conventional wells, and are still present when we control for a large number of previously documented spills. Unknown or undetected spills and leaks could still explain our findings. Independent of the exact mechanism, our results are relevant because we show that the association between unconventional O&G development and elevated ion concentrations extends to many watersheds over several US shales”. We view this paper in addition to reports from other environmental groups will form the framework for a new lawsuit against the EPA in dealing with drilling waste; we see this lawsuit brought in early 2022.

EPA today and the looming regulatory review, HR 1512

As discussed earlier, the EPA is required by law to review its oil and gas policies no less than every three years. This timeline has been circled, and we are seeing discussion of it in congressional committee hearings. Recently the EPA has hired a new Deputy Director for the Office of Resource Conservation and Recovery. This department oversees RCRA, and from whose office we are likely to see the new oil and gas waste review. Clean Futures Act. HR 1512, Section 625 of the bill directs the EPA administrator to review the E&P waste RCRA exemption and determine if it should be regulated as a hazardous waste.

Consequences of rapid regulatory change and the threat of being left behind

Should the EPA determine that oil and gas waste regulatory policy more closely reflect that of other extractive industries, we see Oklahoma at risk of being left behind with the ascension of ESG in the context of drivers and stakeholders. In a recent IOGCC meeting, it was said that “resisting the ESG movement is like opposing the tides you may not like it, and it may be inconvenient, but it’s real and not going away.” “Incumbent upon the industry to find a way to engage, it’s important to note that the people that make up these oil and gas companies don’t resent this movement. They become engaged and are passionate about finding ways to operate the business profitably and in a way that is protective of the environment. The truth is companies can do both, and the ones that don’t might be left behind. There is a fiduciary duty for oil and gas in the global economic transition because the truth is that oil and gas will be required to sustain and raise the global standard of living for billions of people. As US hydrocarbons increasingly become global, we must also keep in mind the issues of sustainability and environmental stewardship will become increasingly important in the competitive marketplace. Proper disclosure and waste management avoid unnecessary legal and social risk and value crates and gives a competitive advantage for companies seeking capital in an increasingly challenging time. “

Conclusion: How Oklahoma can adapt and survive

Oklahoma still has time to modernize its regulatory framework, attract investment dollars, build out the needed infrastructure required to save valuable, high-paying oil and gas jobs, and do it in a way that lowers costs for the operators. The following are simple recommendations that would start to bring us into parity with other producing states:

- Reinstate the prohibition on land spreading of oil-based mud

- Prohibit or restrict the use of “temporary pits” except in emergency situations

- Develop new guidelines for the permitting and operation of modern commercial waste management facilities

- Develop new recycling guidelines that focus on true recycling instead of dilutionary methods

- Require groundwater monitoring for land where multiple land application events have occurred and for all future multiapplication sites.